Product Description

| Model | WER-EW160 |

| Print heads | Precision indusrial piezoeltefric nozzle |

| Ink type | Aqueous dye , sulimation ink |

| Max printing width | 1800mm |

| Max printing reolution | 2880dpi |

| Power supply | ac200v, 50-60hz |

| Wattage | 500-6500w |

| Machine size/N.W. | 3100X2200X1400mm |

| Package size/G.W. | 3300x2500x1500mm |

| Print speed | 60m2/h standard mode, 40m2/h high quality mode, 30m2/h high precision mode |

Detailed images

High speed digital divect injection printer

1.Ink cartridge 2.Collecting shaft 3.Power master switch 4. Magnetic powderregulator 5.working table 6.Control panel 7. speed controller 8.operation panel 9.Wire rod 10.stop switch

Product Feature

1. Roller surface with Teflon coat, high hardness,wear resistant,anti-sticking

2. Digital temperature and speed hardness,wear resistant,anti-sticking

3. Oil heating,temperature uniformity (±1-2°C) no deviations of color.

4. Using imported heating pipes,heat evenly,durable;imported blankets which is not easy to deviate.

5. The blanket is detachable,and not easy to burn;with belts putting device for installing and fixing the belts.

6. Without smoke and abnormal odour during working.

equipment advantage

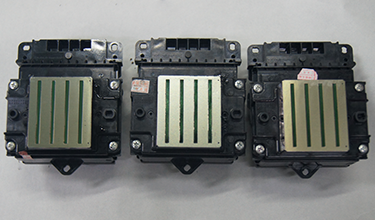

5113 nozzle

Each of imported 5113 nozzle has 3200 holes, which makes inkjet faster.

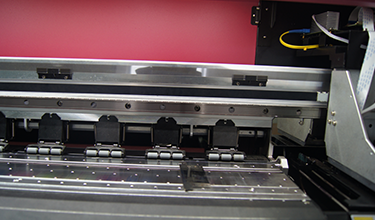

Japanese imports THK guide

Using Japanese imports THK silent rails, it could achieve high-precision linear motion in the case of high load.

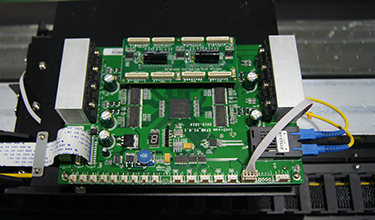

Independent research and development board card

By perfect combination of Board and 5113 nozzle , the machine has high precision inkjet and print faster .

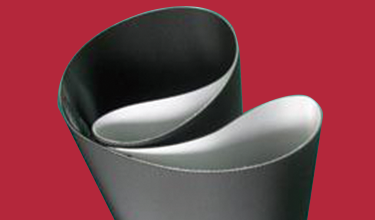

Swiss import conduction band

Conveyor of imported materials is smooth and wear proof, enjoying a long service life without deviation.

Automatic cleaning system

Using imported heating pipe, it can save energy and work durably, at the same time ,it has cold air device, which is helpful to dry the surface of the fabric and roll together.

Application:

Apply to pure cotton, linen, silk, canvas, leather and other digital direct inject printing.

Packing Details:

Heat transfer printing machine packing will be made according to customers’ requirements.

Here is safe packing method as below:

Machine will have PVC bag and foam inside ,iron frame outside.

Iron frame is used for all parts of the machine together and protect the macine.

Our Services

1. Strict quality control

2. Professional suggestion

3. Perfect and complete after-sale service.

4. OEM are available.

5. Quick delivery.

6. Standard Packing

7. Good reputation

8. Professional production and sales team

FAQ

1.When can I get the quotation ?

We usually quote within 24 hours after we get your inquiry. If you are very urgent to get the price, please call us or tell us in your email so that we will regard your inquiry priority.

2.How can I get a sample to check your quality?

After price confirmation, you can require for samples to check our quality counter display.

If you need the samples, we will charge for the sample cost .But the sample cost can be refundable after order confirmation when your quantity of the order is more about the MOQ.

3.What kind of files do you accept for printing?

PDF, Core Draw, high resolution JPG

4.Can you do the design for us?

Yes. We have a professional team having rich experience in gift box design and manufacturing. Just tell us your ideas and we will help to carry out your ideas into perfect watch boxes. It does not matter if you do not have someone to complete files. Send us high resolution images, your Logo and text and tell us how you would like to arrange them. We will send you finished files for confirmation.

5.How long can I expect to get the sample?

After you pay the sample charge and send us confirmed files, the samples will be ready for delivery in 3-7 days. The samples will be sent to you via express and arrive in 3-5 days. You can use your own express account or prepay us if you do not have an account.

6.What about the lead time for mass production?

3d t-shirt printing machine Honestly, it depends on the order quantity and the season you place the order. The lead time of MOQ is about 10 to15 days. Generally speaking, we suggest that you start inquiry two months before the date you would like to get the products at your country.

Quick Details

Type: Inkjet Printer

Condition: New

Plate Type: direct digital printing machine

Place of Origin: shanghai, China (Mainland)

Brand Name: wer

Usage: Bill Printer, Card Printer, Cloths Printer, Label Printer, Paper Printer, Tube Printer

Automatic Grade: Automatic

Color & Page: Multicolor

Voltage: 110V/220V

Gross Power: 200-2500W

Dimensions(L*W*H): 3070x750x1380mm

Weight: 2500kg

Certification: CE Certification

After-sales Service Provided: No overseas service provided

Key words: digital textile printing machine

Color: Red , blue

Ink type: C , M , Y , K

Print head: 5113

Print speed: 40-60 m/h

Product name: digital textile sublimation ink jet printer

Max printing Width: 1850 mm

Application: Transfer paper

Warranty: 12 Months