overview

Print Technology: Drop-On-Demand piezoelectric technology

Head Type: Epson DX5 printhead / Epson DX7 printhead

Nozzles: 180 nozzles*8 lines

Height of Print Head: 1.2mm / 2.8mm above media, adjustable

Safe Cover: Automatic offline function’s safe interlocking device

Sepcification

| Model | EW160 | EW160I | ||

| Print Technology | Drop-On-Demand Piezoelectric Technology | |||

| Ink type | Sublimation ink | |||

| Color model | Double CMYK | |||

| Nozzles | (180 nozzles*8 lines)*1 head | |||

| Head type | Epson DX5 | Epson DX7 | ||

| Height of print head | adjustable from 1.5mm to 2.5mm | |||

| ink supply method | Block gate-type | |||

| Feed up method | Multi-press feed paper | |||

| Usable medias | Poster, Banner, mesh, PVC vinyl, perforated vinyl, photo paper, backlit film | Sublimation paper, fabric, polyester fleece blanket, shower curtain, Etc | ||

| Media width max | 1580mm | |||

| Print width max | 1520mm | |||

| Print margin minimum | 5mm | |||

| Print resolution & print speed | Resolution (DPI) | Speed | ||

| 540*720dpi (6 pass) | 10.5m2/h | |||

| 720*720dpi | 4 pass | 15.0m2/h | ||

| 8 pass | 7.7m2/h | |||

| 1440*720dpi (8pass) | 3.4m2/h | |||

| 1440*1440dpi (16pass) | 1.7m2/h | |||

| Media roll outer diameter | 2 inch or 3 inch | |||

| Heater system | The heaters for front and center platform separately | |||

| Media type | Single paper (feed front), Roller paper (feed rear) | |||

| Max weight for roll media | 40KGs | |||

| Interface | USB2.0/HiUSB | |||

| EMS memory | 128M | |||

| RIP Software | Maintop&Wassatch | |||

| Print language | Standard printer languages | |||

| Power supply | Ac100-120V&Ac220-240V (Adaptive) 50/60Hz+/-1Hz | |||

| Power | working condition | 100W | ||

| Consumption | Standby mode | 40W | ||

| Acoustic noise | <50dB | |||

| Environment | Temperature: 20℃~32℃; Humidity: 40%~60% | |||

| Weight of printer | 200KGs | |||

| Packing & Delivery: | ||||

| Weight with packing | 288KGs | |||

| Packaging: | To be packed with Timber with fumigation certificate | |||

| Packaging Size | 255*90*60CM | |||

| MOQ | One set per order | |||

| Delivery | 7 working days after receive the deposit | |||

Quick Details

Place of Origin: Shanghai, China (Mainland)

Brand Name: WER

Model Number: WER-EW160

Plate Type: inkjet Printer

Usage: indoor Printer

Color & Page: Multicolor

Automatic Grade: Automatic

Condition: New

Dimension: 2680mm*870mm*940mm

G.W.: 250 KGS

Certificate: CE

Products Details

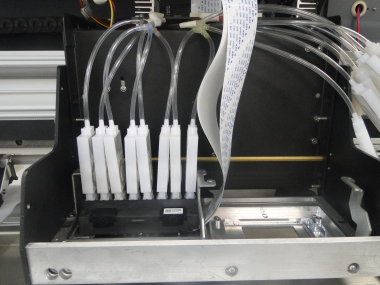

DX5 Printhead

Instruction: Epson DX5 Resolution: 1440DPI

Color: 4 colors

Print mode: 4, 6, 8, 12 Pass

Notes:

A: Operators need to make antistatic treatment, please wear the Anti-static devices if permission, to prevent the high static load from burning the circuit board inside print head.

B: During installation, try not to directly touch the surface of print head.

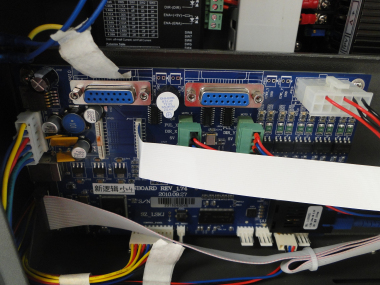

Eco solvent printer main board

Introduction: EPSON DX5 and DX7 eco solvent printer main board.

Usage: Send printing data signal, control the operations of main parts.

Notes:

A: Resist dirt and moisture for the main board.

B: Turn off the power when check the main board. Mark the plug signal line and supply line to avoid connection mistake which can burnout the main board.

C: Please do not break or weld the spare parts on the main board personally.

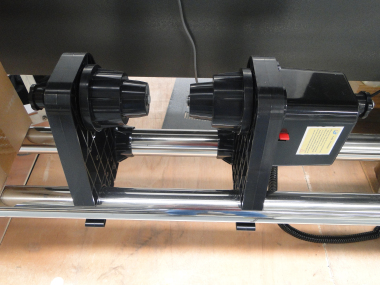

Sheet feeder

Introduction: Auto-feed, keep the material tension balance, make the material pass through the print platform smoothly and do nice printing work.

Notes:

A:. When printing materials, rigidly fix the material and sheet feeder shelf.

B: Try to put the material in middle of the platform, make the material get equal force by the roller, so it can pass through the print platform smoothly.

C:Keep a clean and tidy environment surrounding the sheet feeder; do not interfere with the feeding process

Ink cartridge

Introduction: 2 Liter ink cartridge, provide the ink continuously which is very convenient. Ink color is clear, so it is not easy to add the wrong color ink.

Notes:

A: Make sure each color ink to the corresponding ink cartridge.

B: It is enough when the ink reaches 3/4 of the cartridge.

C: Be careful not to dirty machine and ground when add ink; seal the lid on time after add ink.

Suction and heating device

Introduction: Automatic suction when printing which can make the print materials adsorb to the platform better, so the heater can heat and dry the printed material more evenly.

Notes:

A: Keep the suction plate clean and tidy.

B: Adjust the suction strength before printing, as well as proper heating temperature.

C: Do not touch the heating plate when printing.

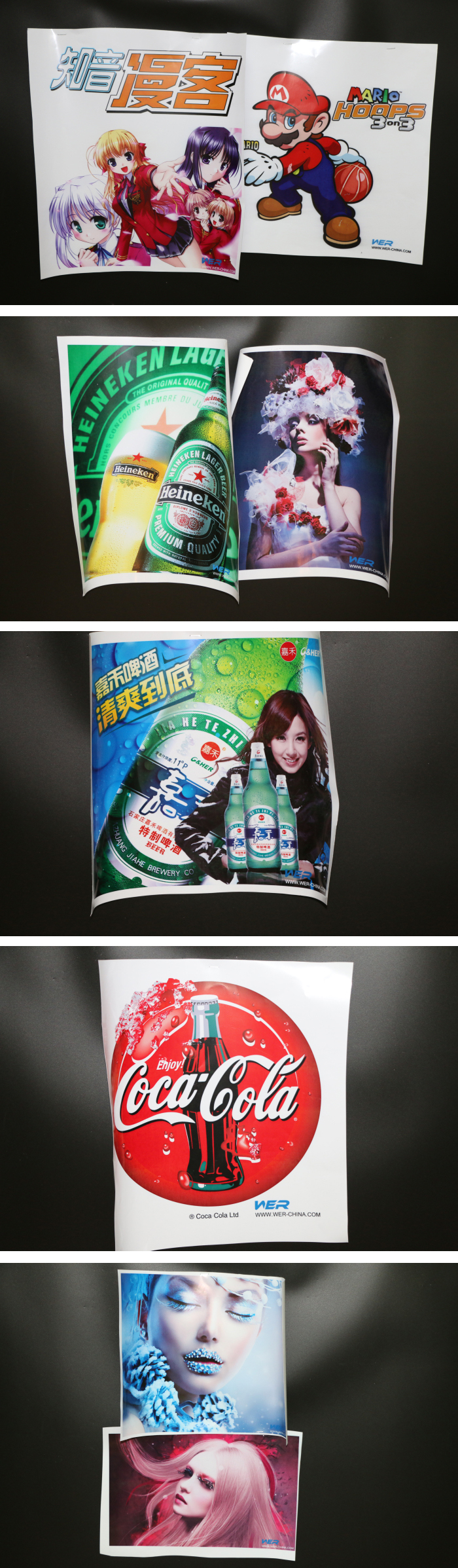

Application Samples