Overview

Easily operated, auto cleaning function and auto height adjustment

Equipped with original Epson R2000 printing system, easily operated with LCD operation panel, auto cleaning function and auto height adjustment ,WER-E2000 Phone Case printer offers all the benefits of the smaller uv printer with even greater versatility and spectacular photo-quality print reproduction onto an almost limitless range of materials.

Multi-function and perfect industria

l design

With the capability to print into thick substrates, it offers the ability to produce a diverse range of prints for both indoor and outdoor use. It is ideally suited for applications such as phone case, promotional items, signs, pens, ceramic, glass and metal decorative panels and more. Its maximum printing size is 329mm*600mm, which is enough to fit into most sign and graphic print shops. White, clear and color inks are available.

The UV-LED lamps offer reduced energy consumption and a longer lamp lifetime.WER-E2000 Phone Case printer opens up a whole new world of possibilities for the end-user in the higher volume production market.

specifications

Specifications Of Epson E2000 A3 Phone Case Printer

| Printer Model | WER-E2000 Phone Case Printer | |

| Printing tech | Micro Piezo Technology | |

| Nozzle number | 1440 | |

| Max print size | 270mm*550mm | |

| Accept material's height | 17cm | |

| Print resolution | 5760*2880 dpi | |

| Print quality | True Photographic quality | |

| Printing Direction | Smart Bi-directional Printing Mode | |

| Printing speed | 720 dpi 25 seconds/A4 size | |

| 1440 dpi 50 seconds/A4 size. | ||

| 2880 dpi 110 seconds/A4 size. | ||

| Cooling Method | Water cycling cooling system | |

| Auto adjustment function | Nozzle automatic detection; print head automatic aligning | |

| Applicable industry | Rigid PVC board, glass, plastic, organic board, leather, rubber, special paper, metal, wood, porcelain, PVC, ABS, acrylic, aluminum, iron sheet, ceramic tile, glass, marble, granite, paperboard etc | |

| Operating system | Windows XP/ME/Vista/Win7/MAC | |

| Interface | Double USB port | |

| Languages | English, Chinese. | |

| Ink colors | Dual CMYK or CMYK+WWWW or CMYK+WW+VV | |

| Ink type | UV LED curing ink | |

| Lamp type | LED Lamp (saving energy and environmental friendly) | |

| Ink system | CISS built inside | |

| Height adjustment | Automatic with sensor. | |

| Driving power | 110 V/ 220 V. | |

| Power consumption | 136 W/ Hour. | |

| Ink consumption | 10 ML/SQM. | |

| Working environment | 10-35 Celsius | |

| Software | Photoshop, CorelDraw, Illustrator, WER RIP, | |

| Media feeding system | Auto or Manual | |

| Packing & Delivery: | ||

| Gross weight | 150 KGs | |

| Packing | To be packed with Timber with fumigation certificate | |

| Packing Size | 1130*1130*850 mm | |

| MOQ | One set per order | |

| Delivery | 7 working days after receiving the deposit | |

features

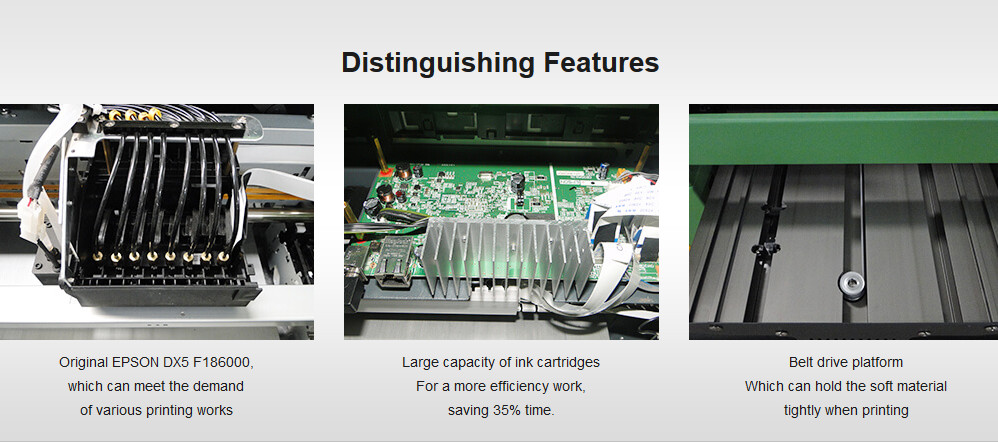

Advanced Printing Technology:

The E2000 ink system is based on an advanced LED UV curing system. It uses proprietary direct to substrate LED UV ink. The LED UV ink technology allows the creation of amazing 3D textured and raised printing effects.

Flash On Ink Firing System

Intelligently powered by FOIF system, the E2000 Phone Case printer electronically activates the UV LEDs when firing ink only. As a result the life time of the printhead and the UV LEDs is maximized. FOIF also protects the entire ink system including the ink pump, the wiper, the damper, and the cap tops.

Control On Demand System

Designed for an enhanced flexibility and simplicity, COD digitally controls the operation of the LED UV system. It automatically adapts to different materials and working environments. COD controls the UV Curing mode(Bi-directional, Uni-directional). This will result in delivering an optimal printing quality and drying time.

Safe Water Cooling Control System

Designed for operational extra safety and simplicity, SWCC system is built on a digital industrial chilling system. It recycles 300ml of an industrial cooling liquid. The liquid level is visible and refillable on demand to avoid the wearout of the UV LEDs.

Automatic Printhead Height Adjustment

Designed for operational extra safety and simplicity, SWCC system is built on a digital industrial chilling system. It recycles 300ml of an industrial cooling liquid. The liquid level is visible and refillable on demand to avoid the wearout of the UV LEDs.

Continuous Ink Supply System

Unlike ink cartridges, this system allows for 100% utilization of available ink.

Remote Control Panel

The RCP is a software module allowing the remote administration of the printer from your desktop computer.

Easy leave

Automatic ink system cleaning by time setting prevent head clog.

applications

After 10 years’ of experience and exploring in printing industry,WER UV series mainly used for the following media as well:Rigid PVC board, plastic, organic board, leather, rubber, special paper, wood, porcelain, PVC, ABS, acrylic, aluminum, ceramic tile, marble, granite, paperboard etc

Logo, Sign

Signs and logos, the perfect effect comes out from our printer, make our life more convenient. No matter it is regular shape or irregular shape, whether it is wood, PVC, acrylic or metal materials, our printer can print what you want in high-quality and rich color.

accessories

| No. | Item | Unit | Discription | Warranty | Function | Price |

| 1 | Printhead | Pcs | EPSON F186000 DX5 Second encrypted | No | Physical resolution control | |

| 2 | Mainboard | Pcs | Yes | Printer data control | ||

| 3 | MCB board | Pcs | Yes | Data transfer | ||

| 4 | PCB board | Pcs | Yes | Driver system | ||

| 5 | Servo motor | Pcs | No | Drive control | ||

| 6 | Servo motor driver | Pcs | No | Driver software for servo motor | ||

| 7 | Power supply | Pcs | No | Power control | ||

| 8 | UV Lamp water cooling box | Pcs | No | Cooling system | ||

| 9 | Printhead data cable | Pcs | No | Printhead data cable transfer | ||

| 10 | LED UV Lamp | Pcs | No | LED UV drying system | ||

| 11 | Ink damper | Pcs | No | Ink filter | $9.99 | |

| 12 | Ink tube | Pcs | No | Ink transfer | ||

| 13 | Wiper | Pcs | No | Scrape the waste ink | ||

| 14 | Motor belt | Pcs | No | Driver system | ||

| 15 | Carriage belt | Pcs | No | Driver system | ||

| 16 | Cleaning unit | Pcs | No | Printhead cleaning system | ||

| 17 | LCD touch screen | Pcs | No | Touch screen panel | ||

| 18 | Ink cartridge | Pcs | No | Ink container | ||

| 19 | Raster reader | Pcs | No | Data transfer | ||

| 20 | Raster sensor | Pcs | No | Data transfer | ||

| 21 | Ink chip | Pcs | No | Driver system |

Price description

For the above items, there are some consumable parts (like printheads) and some Non vulnerable parts, so WER company just offered some of the prices as reference. If you need the exact price, please feel free to contact our sales staff.

| No. | Discription | Quantity | |

| 1 | USB data cable | 1 | Free |

| 2 | Funnel | 5 | Free |

| 3 | Ink chip | 8 | Free |

| 4 | Ink chip refresh | 1 | Free |

| 5 | Ink tube | 2 m | Free |

| 6 | Ink capping top | 1 | Free |

| 7 | UV Ink damper | 4 | Free |

| 8 | Syringe | 5 | Free |

| 9 | Software and user manual | 1 set | Free |

| 10 | Power cable | 2 | Free |

Attention

1. When the equipment sent to the customers and ready to all install, the first thing is to prepare a voltage regulator, while civil voltage is stable now, but still there will be some floating up and down. Because of the voltage instability, which will have some difficulty in installation. The problem we met mostly may be the connection to computer, or after the online software can't normally opened, also is the computer power cord unexplained fever, which may affect the equipment! At this time we are going to use multimeter to measure the voltage to solve this matter!

2. When we switch on, machine reset successfully, then we open software. Since the connection when the machine is reset software absorbing ink pad will be a process of down and up, the device is reset, so as to lead to errors instructions, machine reset failed!

3. When using the equipment, printing products if happens to catch up with something not in, so it is better to turn off the software. Because the device under the connection state of software will continue to control flash spray nozzle, after a long time will lead to absorb ink pad ink spill over into the ink pad on the lines below, after a long time will affect the equipment!

4. If our production is completed, shut off the device, the software must be closed first.

5. Before you insert the data cables, turn off the printer power first.

6. Before printing works, you should make sure printheads don't hit print media, adjusting the nozzle height then send the print task.

7. Often clean the printhead and the printhead stays wet, prevent drying printhead from affecting the service life of the nozzle.

8. The machine doesn't work, don't inject ink into the cartridge.

9. If you haven’t operated the machine for a long time, clean up to remove the nozzle with a cleaning fluid stays wet.